Last Updated on January 1, 2024

If you are living in a region where climate is dry or moderately humid it is a good idea to use a swamp cooler. You might in fact be using it. It is a major distress if you have taken it out for summer to control heat and it keeps shutting off.

Swamp cooler keeps shutting off majorly due to motor overheat. Overheating occurs due to high belt tension, lack of lubrication or too high voltage. Inappropriately located or faulty thermostat may also result in continuous shutting of swamp cooler.

The most critical component of an evaporative cooler that is most prone to failure is the motor. Motor is the source of all the energy transferred to your blower wheel that then delivers cool humid air to you. The pump is also powered by the motor.

Why Your Swamp Cooler Keeps Shutting Off?

There are several reasons why your swamp cooler turns off after few minutes of operation and then turns back on. The most common cause of this intermittent operation is overheating of motor. The reason why the motor does not simply burn is the presence of thermal protection. It protects the motor from simply burning.

When temperature is reached that is too high the electric current is cut off to protect motor. After sufficient time when the thermal conditions are recovered the motor turns back again.

It is highly like that overheating is the reason of your swamp cooler shutting off. However, there are other reasons too. Below is the list of the most probable causes for it;

1. Inadequate Belt Tension

Air is delivered out of your evaporative cooler by rotation of blower wheel. The energy is provided to blower wheel by a motor. The rotational energy is transferred from the motor to the blower via belt.

The belt tension has to be right so that the smooth transfer of energy is carried out. It should neither be loose nor tight.

If the belt is too tight, then it will cause stress on motor bearings. As a result, it could over amperage your motor and overheat it maybe eventually causing permanent motor failure. The increased stress will cause squeaking or squealing sound during the operation.

If the belt is too loose, it will result in slippage, causing friction over the pulley and reducing the life of your belt. You will have to change it much sooner than you are supposed to.

Fortunately, it is convenient to adjust belt tension.

Just by making simple adjustment you can achieve correct belt tension. The proper tension of the belt is actually the lowest tension at which the belt won’t slip.

Tips and Steps to Diagnose and Fix

- You can check the tension by squeezing the belt from in between of motor and blower wheel center. It should have a deflection of 1/2 to 3/4 of inch from either side.

- Loosen the bolt of the motor bracket.

- Move the bolt outside to tighten and move it inside to loosen belt.

- After you have achieved the recommended deflection on either side, tighten the bolts and you are good to go.

There may be some differences in the location of bolts and fixture of motor. However, the basic procedure is almost the same as above. It would be easy to figure it out.

2. Malfunctioning or Inappropriately Located Thermostat

A digital thermostat allows to achieve the desired temperature. Normally a traditional swamp cooler will have limited options such as ON, off, pump and fan speed.

However, you will not be able to adjust the temperature of your choice and will have to manually operate the swamp cooler by yourself. This will in turn show on your electricity bills and reduce the efficiency of the system.

Not able to adjust the temperature correctly will also reduce your comfortability.

A thermostat also enables to add what is called a timed delay.

When you have just started your swamp cooler it will deliver warm air initially until the cooler pads soak in the water and the evaporative cooling process is initiated.

Timed delay in thermostat resolves that by turning the fan ON only when pads are soaked, and air blown is cool.

In case your thermostat placement is wrong it can result in inappropriate shutting of swamp cooler. The swamp cooler is perfectly fine in this situation.

It is possible that there is no motor overheat, or anything wrong with the electrical connections, but due to the wrong location of the thermostat, it is detecting unrealistic temperatures.

As soon as the thermostat detects wrong temperature it considers that the room is cool. It turns the swamp cooler off. As deflection is unrealistic and sudden thereby the sensor keeps detecting deviation in the temperature. As a result, swamp cooler intermittently turns ON and OFF.

So give a check to location of your swamp cooler thermostat.

Make sure thermostat is not in the path flow of cool air from the swamp cooler. It should be in a location that is actually away from the swamp cooler ideally the center of room.

In this way, it would detect realistic temperatures, after the thermal equilibrium is attained, or in other words, the temperature in all parts of the room is same.

Also make sure that thermostat sensor is away from direct sunlight, kitchen and other sources of air like windows and doors. These locations can also result in wrong temperature detection or sudden deflections.

3. Dried-Out Bearings

One of the reasons for your swamp cooler shutting off repeatedly is bearings. If bearings are not lubricated properly this could result in overheating of the fan motor leading to shut off.

You should periodically oil the bearings of your cooler to keep them spinning smooth and free. This will also improve the life of your bearings and prevent replacing them.

Oiling is very easy to do so. Normally, you should oil the bearings once a year. This would prevent from going through inconvenient process of changing the bearings.

The procedure is super simple…

- Open up the side panels of your swamp cooler.

- Locate the bearings in the swamp cooler which you have to oil. Generally, a traditional swamp cooler has two bearings.

- On the top of the bearing housing, you will see two holes for the purpose of lubricating the bearings. They may be covered.

- Remove the covering and add the lubricant in each of the holes. You are not required to use just the right quantity of oil, just use that would be enough.

- Turn the blower wheel to spread the lubricant over the surface of bearings. After you are done, cover the holes and attach the side panels just the way they were. You are done.

For lubrication any all-purpose lubrication oil would do the job. You may use Zoom Sprout Cooler Oil that is specifically designed for this purpose. The same oil can be used for lubricating motor bearings too.

Though most of the swamp cooler motors are permanently lubricated. You may also have to lubricate motor bearings. Check for oil caps on either end of the motor and add oil. Doing so take care not to overfill. Turn the blower wheel by hand to spread the lubricant over the surface of bearings.

4. Faulty Electrical Components/Connections

If you have problems with electric wiring of your swamp cooler motor, it can also lead to repeated shutoffs. Electric components and switches could also be a reason to that. They are constantly exposed to moisture that can result in corrosion and prevent the current to appropriately flow through them.

Inspect electrical connections and components for heating or electrical shortages. Diagnose bad switches and fuses that may be reason of continuous heating of swamp cooler motor.

Inspect wires connected to thermostat and switches for controlling the operation of swamp cooler.

If you have problems with wires, replace them. If wires are OK, inspect the switch and replace if faulty. It is not hard to do so if you have a little experience.

Extra Information for Experienced Individuals

Identify the function of each wire, it will help you diagnose. Normally, green is for ground, white for common. Green never takes current it is just a safe path to the ground and white that is common is actually dead and OFF state for cooler. The other three represent ‘vent high’, ‘vent low’ and ‘pump only’. Sometimes wires are not hooked correctly, and you need to test them. The video below will help you understand swamp cooler wiring better.

Be very careful in your diagnosis of anything related to electricity yourself. Don’t have any experience, just call a technician, you are worth a lot more.

5. Inadequate Voltage to Swamp Cooler Motor

Your swamp cooler motor is designed to operate below a certain voltage limit. If the voltage is increased above that limit it will result in overheating of the motor.

Eventually after achieving certain high temperature motor will shut down to protect itself by the assistance of internal protection system. It will turn back on when the temperature is reduced. It will look like swamp cooler is arbitrarily turning on and off.

So check you motor specifications and know the voltage that is required for it to operate. Make sure that you are not using higher voltage than the prescribed limit. Continuously operating your motor like that may cause damage to internal circuitry and wiring or cause permanent damage.

6. Faulty Float Switch

Low water levels can be detrimental to your swamp cooler. If the water level in your cooler tank drops sufficiently low, your pump will go through a ‘dry run’.

Actually, there is no additional lubricant in a swamp cooler’s pump. So if it runs out of water, it will be detrimental to its internal components due to high friction between them.

Fortunately, most modern swamp coolers have an automatic low-water shutoff feature. This means, when the water level goes very low for the pump to operate, an indicator light will be turned ON and the pump will shut off for its protection.

If your swamp cooler turns OFF now and again, it might be due to a faulty float, automatic shutoff switch, or other circuitry attached to it. They may not be operating properly with the water level in your swamp cooler tank.

Tips and Steps to Diagnose and Fix

- I would recommend giving a check to your swamp cooler float. Make sure it is free to move up and down and adequately buoyant with the water level.

- If the float looks good, then the next possible issue related to this component could be the automatic shut-off switch.

- It is simple to diagnose if your cooler has a low water level indicator light. If that light is turned ON, despite the cooler tank full of water, you would know that the automatic shut-off switch is faulty.

- If that is not the case, get it checked by a technician. In case the automatic low water shutoff switch is faulty, try replacing instead of simply bypassing it to protect your evaporative cooler pump.

7. Defective Control Panel or Its Components

If either one or both core mechanical components i.e., fan motor and pump are running intermittently, maybe there is a problem with your control panel.

If this seems to be the case, I would personally first look at the low water level indicator light.

If water level in the cooler tank is good, and the indicator light is still ON, I would know my cooler float or electronic components attached to it are at fault, which is preventing my cooler to run continuously.

By the way, you only have to do that if your swamp cooler has an automatic low water shutoff feature. If not, even if you have the light turned ON no need to look into the float.

Next what I would suspect are the controls in the control panel.

Apart from the potential problems with electrical wiring attached to it, which I have discussed in detail here, I would check controlling equipment, especially in analog ones, that have knobs for regulating the pump and fan operation.

Actually, by turning a knob in a particular direction, you control whether to disconnect the pump or fan or both and also control fan speed. Defective controls can have sparking, shortage, or loose terminals that may turn power to the motor and pump ON and OFF.

Many of these swamp coolers also come with 8, 12, 15 hours, etc. timers. These are mostly digital. But the function of a timer is based on the exact same principle I discussed earlier. It will disconnect the power to the fan and pump when the time is up.

If the problem is electrical, a general diagnosis will save you time. But better not go beyond that for your safety. Get that fixed by a certified technician, preferably the one sent or recommended by the manufacturer.

8. Swamp Cooler Running but Not Cooling

What if the cooler pump and fan both are operating properly and your swamp cooler is not cooling?

It might be that external limitations are the cause of your swamp cooler not cooling more than internal problems.

Let me elaborate a little more…

Your swamp cooler operates by the principle of evaporation. The cooler fan pushes air through cooler pads with water flowing in them. Some water is carried by air. It evaporates and cools the air by taking heat from it. Resultantly, you get cool moist air from the outlet.

However, this phenomenon is dependent on the relative humidity in the air. The more the humidity in the atmosphere, where your swamp cooler is running, the less will be evaporation.

Consequently, a high moisture environment will limit the ability of your cooler to cool.

If humidity exceeds a certain limit for a certain temperature, you can expect inferior operation by your evaporative cooler.

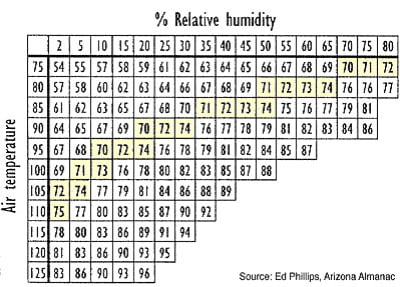

To make it easy I came across this chart that highlights optimal running conditions for your swamp cooler.

This way you can know the effectiveness of your evaporative cooler for particular temperature and humidity conditions in your region.

Be Safe in Your Diagnosis

If even after going through all the common causes you could not diagnose the problem, it is best to call the technician. It is better that you do not go into higher complication to fix your swamp cooler. Especially if you have identified that the problem is most probably in the wiring and you could not figure why the current is not passing through the certain wire or where it is shorted, just call the technician.

Be careful in attempting to diagnose any of the causes described. It is safe though if you take precautionary measures. Cut off all the electricity sources to your swamp cooler before inspection.

Then open up the side panel. Firstly, check for the most probable reasons i.e., motor overheat due to belt tension and problems with bearings. If it keeps shutting off even after fixing them, that is highly unlikely, then check for thermostat, switches, electrical connections, continuity and adequate voltage through motor.